Carmanhaas ZNSE Polished Windows are frequently used in optical systems to separate the environment in one part of the system from another, such as to seal vacuum or high-pressure cells. Because the infrared transmitting material has a high index of refraction, an anti-reflection coating is typically applied to windows to minimize losses due to reflections.

To protect scan lenses from backsplatter and other workplace hazards, Carmanhaas offers protective windows, also known as debris windows that are either included as the overall scan lens assembly part, or sold separately. These plano-plano windows are available in both ZnSe and Ge materials and also supplied mounted or unmounted.

| Specifications | Standards |

| Dimensional Tolerance | +0.0mm / -0.1mm |

| Thickness Tolerance | ±0.1mm |

| Parallelism : (Plano) | ≤ 3 arc minutes |

| Clear Aperture (polished) | 90% of diameter |

| Surface Figure @ 0.63um | Power: 1 fringes, Irregularity: 0.5 fringe |

| Scratch-Dig | Better than 40-20 |

| Specifications | Standards |

| Wavelength | AR@10.6um both sides |

| Total absorption rate | < 0.20% |

| Reflective per surface | < 0.20% @ 10.6um |

| Transmission per surface | >99.4% |

|

Diameter (mm) |

Thickness (mm) |

Coating |

|

10 |

2/4 |

Uncoated |

|

12 |

2 |

Uncoated |

|

13 |

2 |

Uncoated |

|

15 |

2/3 |

Uncoated |

|

30 |

2/4 |

Uncoated |

|

12.7 |

2.5 |

AR/AR@10.6um |

|

19 |

2 |

AR/AR@10.6um |

|

20 |

2/3 |

AR/AR@10.6um |

|

25 |

2/3 |

AR/AR@10.6um |

|

25.4 |

2/3 |

AR/AR@10.6um |

|

30 |

2/4 |

AR/AR@10.6um |

|

38.1 |

1.5/3/4 |

AR/AR@10.6um |

|

42 |

2 |

AR/AR@10.6um |

|

50 |

3 |

AR/AR@10.6um |

|

70 |

3 |

AR/AR@10.6um |

|

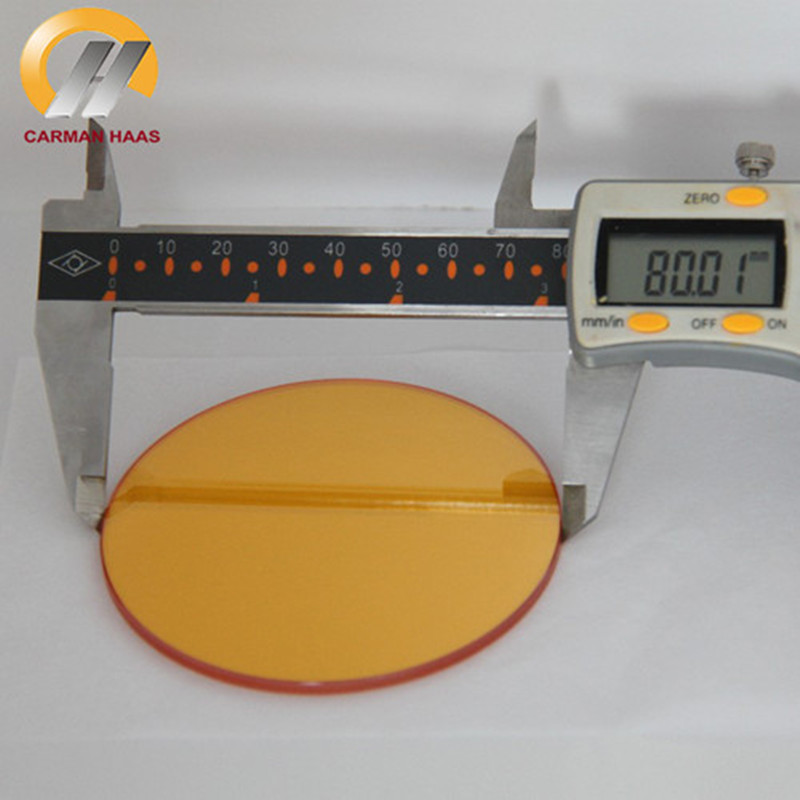

80 |

3 |

AR/AR@10.6um |

|

90 |

3 |

AR/AR@10.6um |

|

100 |

3 |

AR/AR@10.6um |

|

135L x 102W |

3 |

AR/AR@10.6um |

|

161L x 110W |

3 |

AR/AR@10.6um |

Great care should be taken when handling infrared optics. Please note the following precautions:

1. Always wear powder-free finger cots or rubber/latex gloves when handling optics. Dirt and oil from the skin can severely contaminate optics, causing a major degradation in performance.

2. Do not use any tools to manipulate optics — this includes tweezers or picks.

3. Always place optics on supplied lens tissue for protection.

4. Never place optics on a hard or rough surface. Infrared optics can be easily scratched.

5. Bare gold or bare copper should never be cleaned or touched.

6. All materials used for infrared optics are fragile, whether single crystal or polycrystalline, large or fine grained. They are not as strong as glass and will not withstand procedures normally used on glass optics.