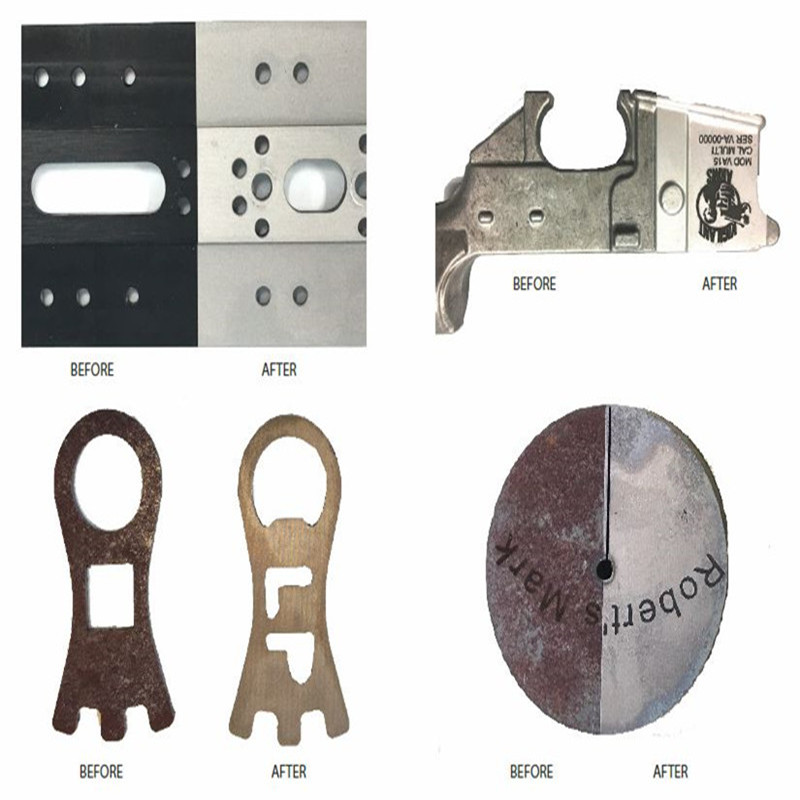

Traditional industrial cleaning has a variety of cleaning methods, most of which are cleaning using chemical agents and mechanical methods. But Fiber laser cleaning has the characteristics of non-grinding, non-contact, non-thermal effect and suitable for various materials. It is considered to be the current reliable and effective solution.

The special high-power pulsed laser for laser cleaning has high average power (200-2000W), high single pulse energy, square or round homogenized spot output, convenient use and maintenance, etc. It is used in mold surface treatment, automobile manufacturing, shipbuilding industry, petrochemical industry, etc. , Ideal choice for industrial applications such as rubber tire manufacturing.Lasers can provide high-speed cleaning and surface preparation in virtually all industries. The low-maintenance, easily automated process can be used to remove oil and grease, strip paint or coatings, or modify surface texture, for example adding roughness to increase adhesion.

Carmanhaas offer professional laser cleaning system. Commonly used optical solutions: the laser beam scans the working surface through the galvanometer

system and the scan lens to clean the entire working surface. Widely used in metal surface cleaning, special energy laser sources can also be applied to non-metallic surface cleaning.

Optical components mainly include collimation module or Beam expander, galvanometer system and F-THETA scan lens. Collimation module converts the diverging laser beam into a parallel beam (reducing the divergence angle), galvanometer system realizes beam deflection and scanning, and F-Theta scan lens achieves uniform beam scanning focus.

1. High single pulse energy, high peak power;

2. High beam quality, high brightness and homogenized output spot;

3. High stable output, better consistency;

4. Lower pulse width, reducing heat accumulation effect during cleaning;

5. No abrasive materials are used, with no problems of contaminant separation and disposal;

6. No solvents are used – chemical-free and environmentally friendly process;

7. Spatially selective – cleaning only the area required, saving time and costs by ignoring regions that don’t matter;

8. Non-contact process never degrades in quality;

9. Easily automated process that can lower operating costs by eliminating labor while giving greater consistency in results.

|

Part Description |

Focal Length (mm) |

Scan Field (mm) |

Working Distance(mm) |

Galvo Aperture(mm) |

Power |

|

SL-(1030-1090)-105-170-(15CA) |

170 |

105×105 |

215 |

14 |

1000W CW |

|

SL-(1030-1090)-150-210-(15CA) |

210 |

150×150 |

269 |

14 |

|

|

SL-(1030-1090)-175-254-(15CA) |

254 |

175×175 |

317 |

14 |

|

|

SL-(1030-1090)-180-340-(30CA)-M102*1-WC |

340 |

180×180 |

417 |

20 |

2000W CW |

|

SL-(1030-1090)-180-400-(30CA)-M102*1-WC |

400 |

180×180 |

491 |

20 |

|

|

SL-(1030-1090)-250-500-(30CA)-M112*1-WC |

500 |

250×250 |

607 |

20 |

Note: *WC means Scan Lens with water-cooling system

Laser cleaning offers multiple advantages over traditional approaches. It does not involve solvents and there is no abrasive material to be handled and disposed of. Compared with other processes that are less detailed, and frequently manual processes, laser cleaning is controllable and can be applied only to specific areas of