Carmanhaas could offer complete laser cleaning optical lens and system solution. Including QBH Module, Galvo Scanner, F-theta Scan lenses and Control System. We are focus on high end industrial laser application.

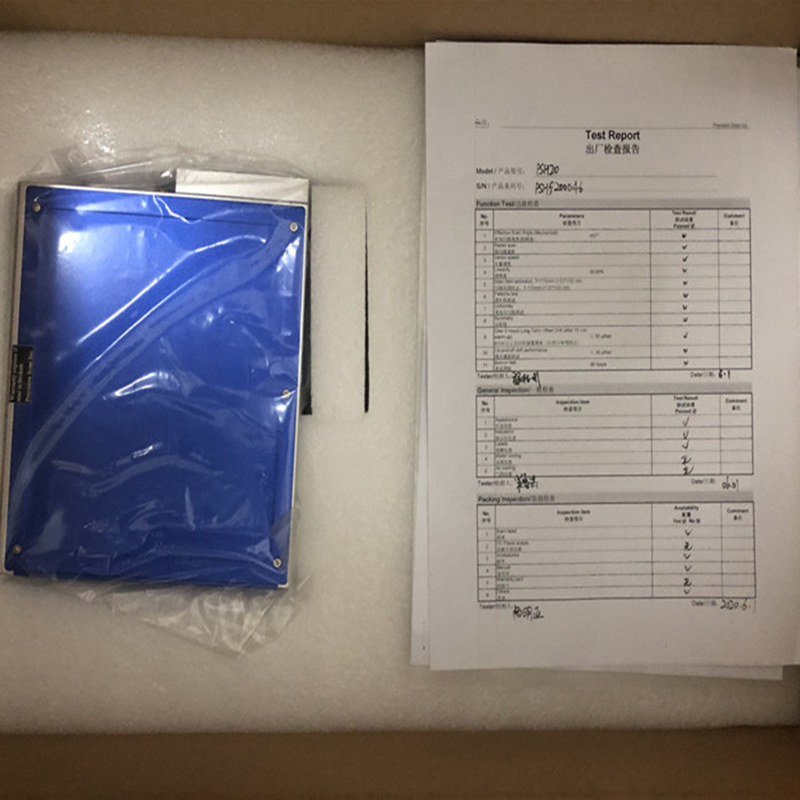

Our Galvo Scanner standard model is PSH10, PSH14, PSH20 and PSH30.

PSH10 version- for high end industrial laser applications, such as precision marking, processing-on-the-fly, cleaning, welding, tuning, scribing, additive manufacturing (3D printing) , microstructuring, material processing, etc.

PSH14-H high power version- for laser power ranging from 200W to 1KW(CW); fully sealed scan head with water cooling; suitable for high laser power, dusted, or environmentally challenging occasions, e.g. additive manufacturing(3D printing), precise welding, etc.

PSH20-H high power version- for laser power ranging from 300W to 3KW(CW); fully sealed scan head with water cooling; suitable for high laser power, dusted, or environmentally challenging occasions, e.g. additive manufacturing(3D printing), precise welding, etc.

PSH30-H high power version- for laser power ranging from 2KW to 6KW(CW); fully sealed scan head with water cooling; suitable for super high laser power, extremely low drift occasions. E.g. laser welding.

1. Extremely low temperature drift (≤3urad/℃); Over 8 hours Long-Term Offset Drift ≤30 urad

2. Extremely high resolution and repeatability; resolution≤1 urad; repeatability≤ 2 urad

3. Super high speed:

PSH10: 17m/s

PSH14: 15m/s

PSH20: 12m/s

PSH30: 9m/s

|

Model |

PSH10 |

PSH14-H |

PSH20-H |

PSH30-H |

|

Input laser power (MAX.) |

CW: 1000W @ fiber laser

Pulsed: 150W @ fiber laser |

CW: 1000W @ fiber laser

Pulsed: 500W @ fiber laser |

CW: 3000W @ fiber laser

Pulsed: 1500W @ fiber laser |

CW: 1000W @ fiber laser

Pulsed: 150W @ fiber laser |

|

Water cool/sealed scan head |

NO |

yes |

yes |

yes |

|

Aperture (mm) |

10 |

14 |

20 |

30 |

|

Effective Scan Angle |

±10° |

±10° |

±10° |

±10° |

|

Tracking Error |

0.13 ms |

0.19 ms |

0.28ms |

0.45ms |

|

Step Response Time(1% of full scale) |

≤ 0.27 ms |

≤ 0.4 ms |

≤ 0.6 ms |

≤ 0.9 ms |

|

Typical Speed |

||||

|

Positioning / jump |

< 157 m/s |

< 15 m/s |

< 12 m/s |

< 9 m/s |

|

Line scanning/raster scanning |

< 12 m/s |

< 10 m/s |

< 7 m/s |

< 4 m/s |

|

Typical vector scanning |

< 5 m/s |

< 4 m/s |

< 3 m/s |

< 2 m/s |

|

Good Writing quality |

900 cps |

700 cps |

450 cps |

260 cps |

|

High writing quality |

700 cps |

550 cps |

320 cps |

180 cps |

|

Precision |

||||

|

Linearity |

99.9% |

99.9% |

99.9% |

99.9% |

|

Resolution |

≤ 1 urad |

≤ 1 urad |

≤ 1 urad |

≤ 1 urad |

|

Repeatability |

≤ 2 urad |

≤ 2 urad |

≤ 2 urad |

≤ 2 urad |

|

Temperature Drift |

||||

|

Offset Drift |

≤ 3 urad/℃ |

≤ 3 urad/℃ |

≤ 3 urad/℃ |

≤ 3 urad/℃ |

|

Qver 8hours Long-Term Offset Drift (After 15min warn-up) |

≤ 30 urad |

≤ 30 urad |

≤ 30 urad |

≤ 30 urad |

|

Operating Temperature Range |

25℃±10℃ |

25℃±10℃ |

25℃±10℃ |

25℃±10℃ |

|

Signal Interface |

Analog: ±10V Digital: XY2-100 protocol |

Analog: ±10V Digital: XY2-100 protocol |

Analog: ±10V Digital: XY2-100 protocol |

Analog: ±10V Digital: XY2-100 protocol |

|

Input Power Requirement (DC) |

±15V@ 4A Max RMS |

±15V@ 4A Max RMS |

±15V@ 4A Max RMS |

±15V@ 4A Max RMS |

Note:

(1) All angles are in mechanical degrees.

(2) With F-Theta objective f=163mm. Speed value varies correspondingly with different focal lengths.

(3) Single-stroke font with 1mm height.