Laser metal 3D printing technology mainly includes SLM (laser selective melting technology) and LENS (laser engineering net shaping technology), among which SLM technology is the mainstream technology currently used. This technology uses laser to melt each layer of powder and produce adhesion between different layers. In conclusion, this process loops layer by layer until the entire object is formed. SLM technology overcomes the troubles in the process of manufacturing complex-shaped metal parts with traditional technology. It can directly form almost completely dense metal parts with good mechanical properties, and the precision and mechanical properties of the formed parts are excellent.

Compared with the low precision of traditional 3D printing (no light is needed), laser 3D printing is better in shaping effect and precision control. The materials used in laser 3D printing are mainly divided into metals and non-metals。Metal 3D printing is known as the vane of the development of the 3D printing industry. The development of the 3D printing industry largely depends on the development of the metal printing process, and the metal printing process has many advantages that the traditional processing technology (such as CNC) does not have.

In recent years, CARMANHAAS Laser has also actively explored the application field of metal 3D printing. With years of technical accumulation in the optical field and excellent product quality, it has established stable cooperative relations with many 3D printing equipment manufacturers. The single-mode 200-500W 3D printing laser optical system solution launched by the 3D printing industry has also been unanimously recognized by the market and end users. It is currently mainly used in auto parts, aerospace (engine), military products, medical equipment, dentistry, etc.

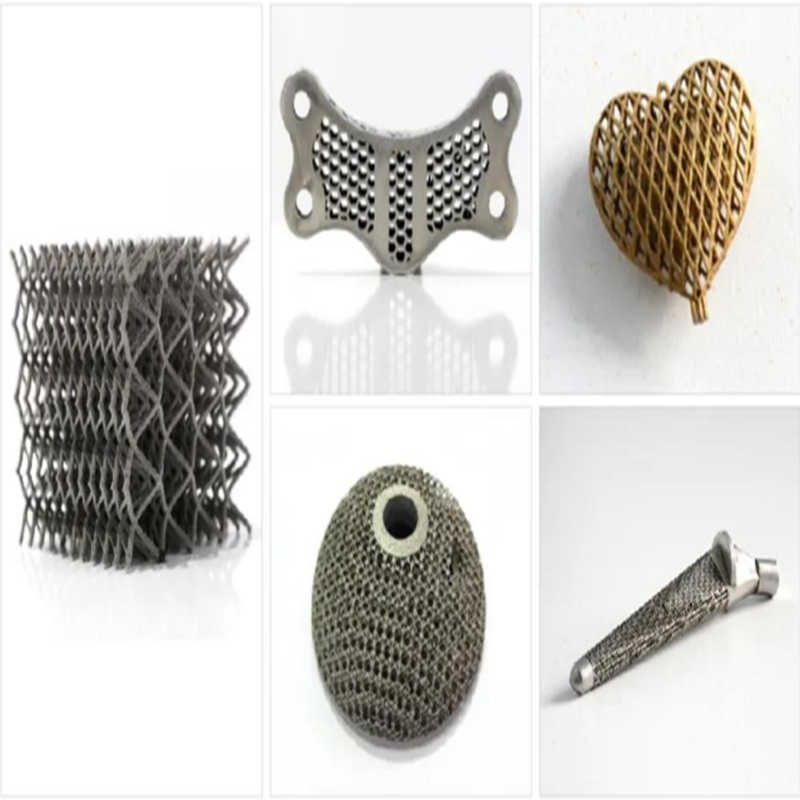

1. One-time molding: Any complicated structure can be printed and formed at one time without welding;

2. There are many materials to choose from: titanium alloy, cobalt-chromium alloy, stainless steel, gold, silver and other materials are available;

3. Optimize product design. It is possible to manufacture metal structural parts that cannot be manufactured by traditional methods, such as replacing the original solid body with a complex and reasonable structure, so that the weight of the finished product is lower, but the mechanical properties are better;

4. Efficient, time-saving and low cost. No machining and molds are required, and parts of any shape are directly generated from computer graphics data, which greatly shortens the product development cycle, improves productivity and reduces production costs.

1030-1090nm F-Theta Lenses

|

Part Description |

Focal Length (mm) |

Scan Field (mm) |

Max Entrance Pupil (mm) |

Working Distance(mm) |

Mounting Thread |

|

SL-(1030-1090)-170-254-(20CA)-WC |

254 |

170×170 |

20 |

290 |

M85x1 |

|

SL-(1030-1090)-170-254-(15CA)-M79x1.0 |

254 |

170×170 |

15 |

327 |

M792x1 |

|

SL-(1030-1090)-290-430-(15CA) |

430 |

290×290 |

15 |

529.5 |

M85x1 |

|

SL-(1030-1090)-290-430-(20CA) |

430 |

290×290 |

20 |

529.5 |

M85x1 |

|

SL-(1030-1090)-254-420-(20CA) |

420 |

254×254 |

20 |

510.9 |

M85x1 |

|

SL-(1030-1090)-410-650-(20CA)-WC |

650 |

410×410 |

20 |

560 |

M85x1 |

|

SL-(1030-1090)-440-650-(20CA)-WC |

650 |

440×440 |

20 |

554.6 |

M85x1 |

1030-1090nm QBH Collimating Optical Module

|

Part Description |

Focal Length (mm) |

Clear Aperture (mm) |

NA |

Coating |

|

CL2-(1030-1090)-25-F50-QBH-A-WC |

50 |

23 |

0.15 |

AR/AR@1030-1090nm |

|

CL2-(1030-1090)-30-F60-QBH-A-WC |

60 |

28 |

0.22 |

AR/AR@1030-1090nm |

|

CL2-(1030-1090)-30-F75-QBH-A-WC |

75 |

28 |

0.17 |

AR/AR@1030-1090nm |

|

CL2-(1030-1090)-30-F100-QBH-A-WC |

100 |

28 |

0.13 |

AR/AR@1030-1090nm |

1030-1090nm Beam Expander

|

Part Description |

Expansion Ratio |

Input CA (mm) |

Output CA (mm) |

Housing Dia(mm) |

Housing Length(mm) |

| BE-(1030-1090)-D26:45-1.5X-A |

1.5X |

18 |

26 |

44 |

45 |

| BE-(1030-1090)-D53:118.6-2X-A |

2X |

30 |

53 |

70 |

118.6 |

| BE-(1030-1090)-D37:118.5-2X-A-WC |

2X |

18 |

34 |

59 |

118.5 |

1030-1090nm Protective Window

|

Part Description |

Diameter(mm) |

Thickness(mm) |

Coating |

| Protective Window |

98 |

4 |

AR/AR@1030-1090nm |

| Protective Window |

113 |

5 |

AR/AR@1030-1090nm |

| Protective Window |

120 |

5 |

AR/AR@1030-1090nm |

| Protective Window |

160 |

8 |

AR/AR@1030-1090nm |